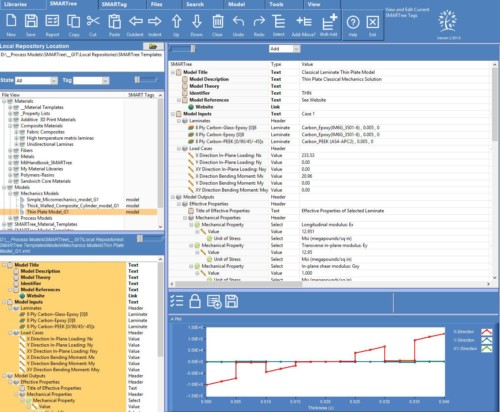

SMARTree software can be used to build and populate a process. Any process can be defined systematically within a tree hierarchy by defining hardware, process conditions and control inputs. These inputs can be single data point entries such as pressure or fixed (perscribed) oven temperature or a table that describes a process history such as a temperature ramp followed by cooldown. Process trees can be built as an output to hardware using an export option or imported from process runs as a record of conditions.

SMARTree software is ideally suited to production management. With its freeform tree and embedded logic, the software can be used to build production or traveler documents to manage part or product workflow. A traveler is used to track a specific batch or lot through a specific production flow. It is typically used as a real-time central information document from where all information regarding that part can be found. SMARTree templates can be built for specific parts or assemblies and populated during production. Subtress such as employee data, raw material information, production equipment, process setpoint and conditions, post inspection trees can be dragged into a part traveler.

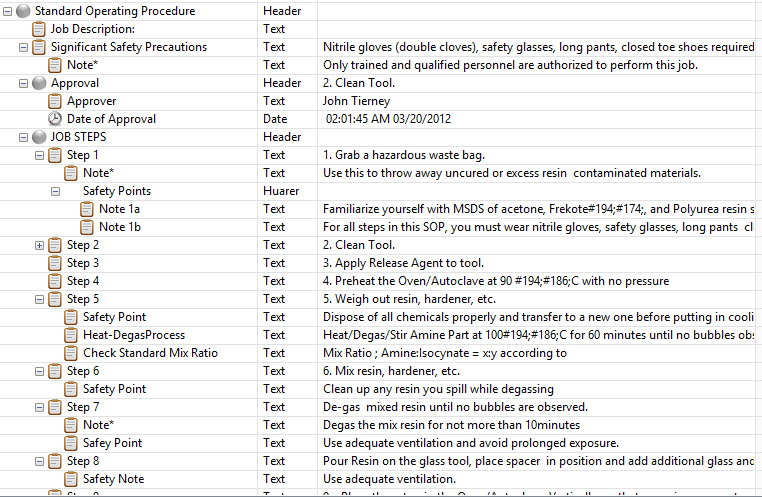

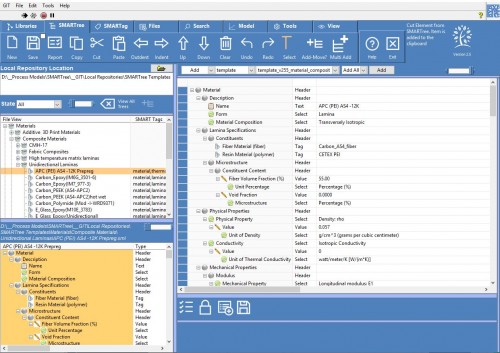

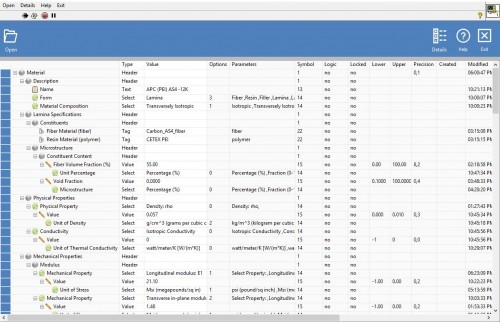

Below is a schematic showing the production steps involved with VARTM (Vacuum Assisted Resin Transfer Molding). This example follows all steps for this process and can include material SMARTrees that document the laminate used in a composite component. The user can drag other trees into this tree below to fully capture the process and then save this tree as a traveler document for each indivdual component in an assembly.